|

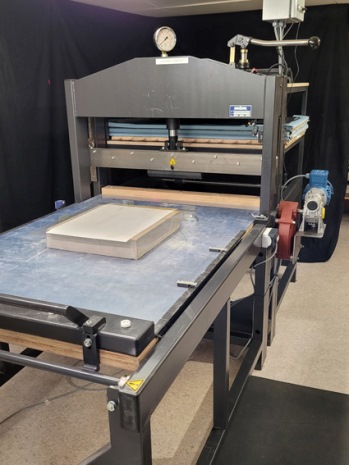

This press was designed and made for heavy duty professional use by the ARTLEY factory in Ghent (Belgium). Artley is world famous for her precise, modern and very sturdy presses. The press has a hydraulic pressure system for the scraper and the bed was originally driven manually. An electronically controlled electric motor (220 V) which moves the press bed forward and back by 2 separate switches was added afterwards. Automatic safety stops are built in. Speed of the bed is variable. The bed stops immediately when the forward or reverse switch is released. The hydraulic pressure system consists of a double action pump. Pressure can easily be adjusted. Exact pressure is indicated in the gauge (diameter 11 cm) on top of the press. The practical working pressure is between 50 and 100 bar or between 750 and 1.500 PSI. The frame is made from heavy duty steel (there are no iron casting parts in the frame). The scraperbox is also of steel and accepts wooden or synthetic scrapers (synthetic scrapers supplied). The press bed moves on 4 ball bearings. The drive cylinder is made of steel, 14 cm in diameter, and rests in self-aligning bearings. All bearings are maintenance free. The gearbox is also maintenance free. The compound gearing is driven by an electric motor or by a handwheel. The motor can very easily be replaced by the iron cast handwheel (diameter 49 cm) and vice versa. Dimensions are:

The press can be disassembled in 3 parts for transport. Gross weight is approx. 1.800 kg. The press is on the ground floor and can be moved out easily. If the electric drive is taken off, (manual drive by hand wheel) Price 7000 Euro The press is located in Belgium |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|