|

|

Printmaking with Solarplate

(photopolymer plates)

|

|

Photopolymerplates are used

in letterpress printing. In the 1960's these polymer plates

started to replace traditional metal plates en lead

characters, effictively freeing industrial printers from the

hazards of poisenes lead fumes generated when making tead

type on composing machines. (Monotype, Linotype). First it

was used in "Flexography" (=printing on flexible material

like cardboard boxes and alike). Later it replaced moore and

moore traditional plate making and lead type. In commercial

printmaking these plates are only used in the relief

printing process, that is why the plates have a certain

thickness. A photopolymer plate consists of three layers;

the steel backing plate, of appr. 0,3mm thick (only a

support), the photopolymer layer (appr. 0,3mm), and on top a

mylar protective transparent layer.

Photopolymer hardens out under the influence of UV-light

(Ultra-violet). Actually; unexposed material are "monomers",

unlinked molecules which can be washed out very easily with

water (+a bit of soda); exposed material is "polymers"

because all the molecules are linked together (=hardened),

and cannot be washed out with water+soda.

Dan Welden (an American

printmaker) found that by exposing a plate in the sun, he

could make a high quality intaglio plate very simply

and cuickly, thus the name "solar plate". Now the technique

is widely known as "solarplate printmaking" or "solar

etching", a term that describes so well the way many

printmakers are working - exposing plates in sunny backyards

and spending more time in the fresh air.

Solarplate

printmaking:

|

|

A

printmaker draws (paints) on a

transparency (mylar, drawing foil, grained

glass, etc).

|

|

|

|

The

transparency is placed face-to-face with

the solarplate and exposed in the sun

(exposure unit). UV-light penetrates clear

areas of the transparency and harders the

polymer, while areas beneath the opaque

lines of the drawing remain soluble. (If

the original is not a line drawing, an

extra exposure through an aqautint screen

is needed)

|

|

|

|

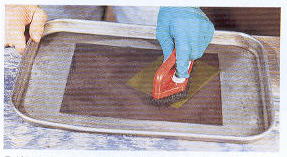

The

plate is scrubbed in tap water (+ a bit of

soda) and the soluble areas are washed

away.

|

|

|

|

Now

the plate needs a final exposure to harden

out all the remaining unhardened

molecules. The plate has grooves and lines

similar to an etched metal

plate

|

|

|

|

The

printmaker inks the grooves and wipes the

surface to create an intaglio print,

or......

|

|

|

|

the

prinrmaker rolls ink on to the surface and

creates a relief print.

|

|

Exposure equipment

- Contact frame. These

frames can come in many shapes. The simplest form is just

a foam "bed", with on top the solarplate, transparent, a

glass plate, and if need some extra weight to press it

all together. The only condition is that there is not a

gap between the tranparent and the solarplate, because

that will lead to an unsharp image. Professional or home

made vacuumframes are better of course.

- Exposure. Sunlight can

be used, but is not always available and gives trouble

calibrating your exposure times. Ready made UV-exposure

units are available; Professional units have a

vacuumframe and a UV-bulb lamp, or a set of UV-tubes. You

can start with a simple UV-bulb lamp+ induction coil.

(Polymetaal # 022545)

Solarplate in Intaglio Printmaking,

general outlines:

|

|

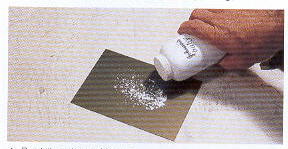

Dust

the plate with talc powder. (to avoid

sticking )

|

|

|

|

Wipe

off excess talc powder

|

|

|

Place

the aquatint screen face down on the

solarplate between glass and the

support.

An aqautint screen is not needed if a line

drawing is concerned.

|

|

|

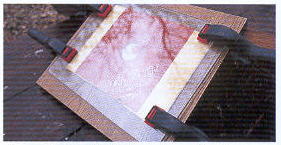

Clamp

and expose.

Clamping is to avoid clearance between the

aquatint screen and the solarplate. If the

support is horizontal, placing some

weights on the glass plate has the same

affect. Exposure can be done in the sun,

as well as in a UV exposure

unit.

|

|

|

|

After

removing the aqautint screen, place the

transparency with the worked surface in

contact with the

solarplate.

|

|

|

|

Clamp

and expose

|

|

|

|

Take

the protective foil aff, and wash the

plate with tap water (+some

soda)

|

|

|

After

blotting, drying and post-exposing, file

the corners of the plate and begin

inking.

Post exposure is very important, to harden

out all the remaining monomer molecules in

the plate.

|

|

|

|

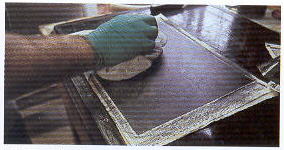

Wipe

with tarlaton and finish with pages from a

telephone book.

|

|

|

|

Print

|

|

For Intaglio printing,

photopolymer film is a good and cheaper alternative.

These films come on rolls and are called "ImagOn-Ultra"

"Puretch" "Z*Acryl-film" "Photec" etc. These films are

traditionally used in the electronic industry to print

circuit boards. Photopolymer plates were originally

developped for commercial relief printing (Flexography). The

thickness of the layer is appropriate for relief printing;

but far thicker then needed for intaglio printing.

Photopolymer films are appr. 30 -50 microns thick ( 0,03 -

0,05 mm). Films are too thin for relief printing, but can be

used very well for intaglio printing. (Both as "Intaglio

Type" (=photopolymer layer carries the ink) as well as

photopolymer film as an "etching resist")

Intaglio photopolymer films are laminated on to a support,

which is normally a copperplate.

Making a relief solarplate from opaque

film

|

|

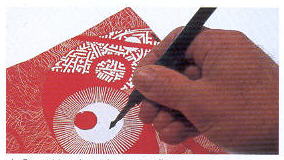

Scratching

through opaque film

|

|

|

|

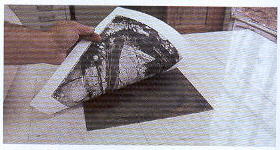

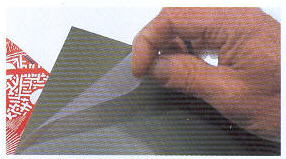

Peeling

the plastic coating from the

solarplate

|

|

|

|

Placing

the image face down on the

plate

|

|

|

|

Exposing

the plate to the sun (or UV-unit) in a

contact frame

|

|

|

|

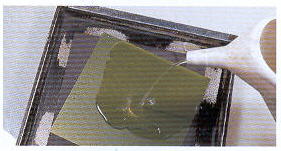

Pouring

water (+some soda) on the

plate

|

|

|

|

Scrubbing

the plate. Observe that the water has

removed the polymer in the unexposed

areas.

|

|

|

|

Post

exposure to harden the remaining monomer

molecules, Rinse the plate in water and

blott the plate.

|

|

|

|

Using

a hair dryer to dry the plate, or use a

drying cabinet

|

|

|

|

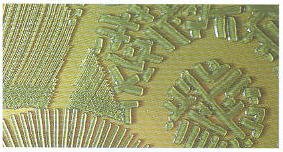

The

relief depth is apparent in raking

light

|

|

|

|

Ink

the plate. The plate can be printed on a

relief press or with a spoon or a baren.

(Japanese style)

|

|

The above gives just an

overview of solar plate printamking. More information can be

found in the following books:

- Printmaking in the sun.

An Artist's Guide to Making Professional-Quality Prints

using the Solarplate Method. Written by Dan Welden and

Pauline Muir. 2001 Watson-Guptill New York.

- Printmaking with

Photopolymer Plates. A new, safe, versatile printmaking

technique for artists and students. Written by Dianne

Longley. 1998 Illumination Press. Adelaide.

|