Instructions for use for the hot plates VL-50x50

- These hot plates can be used for warming up metal plates (usually copper or zinc) as used by etchers. The plate is heated to make the applied etching ink more fluid, allowing the ink to better fill in the etched (or engraved) grooves. The hot plate can also be used very well for applying "soft" or "hard" ground. (acid-resistant substance, with which the plate is locally covered)

- The hot plates are not suitable for melting resin or asphalt powder, as used in "aquatint". The temperature required for this is higher than these heating tables can deliver. Technically it would have been possible to give these tables a higher final temperature. This has been omitted for a number of reasons:

- For melting resin powder or asphalt powder, a temperature of about 200°C to 250°C is required. Given the regulations in the field of safety, it is irresponsible to use this temperature without additional facilities.

- The required electrical power is much greater, which means that a "normal" electrical supply of 220 Volts can no longer suffice. - The heat transfer from the aluminum top plate of the heating table to the heating table may be uneven, especially at these high temperatures. This uneven heat transfer results from the combination of heat transfer by conduction and by radiation. Polymetaal does have a heating table that can deliver much higher temperatures in the program; Series VTS..

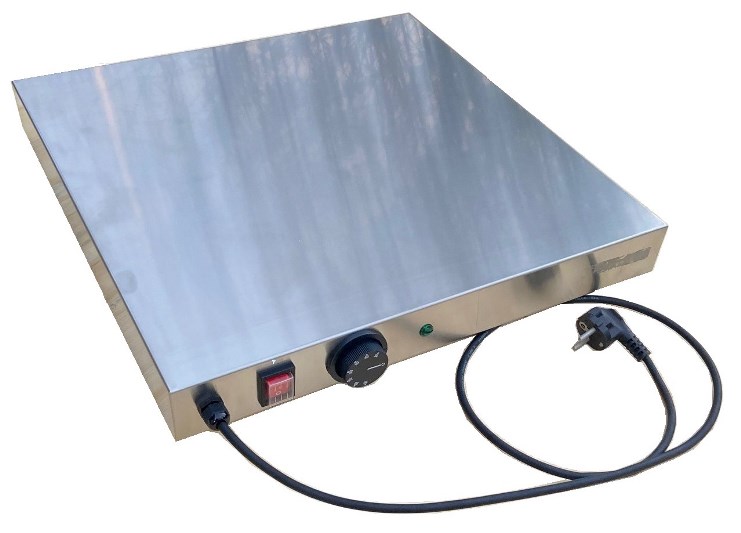

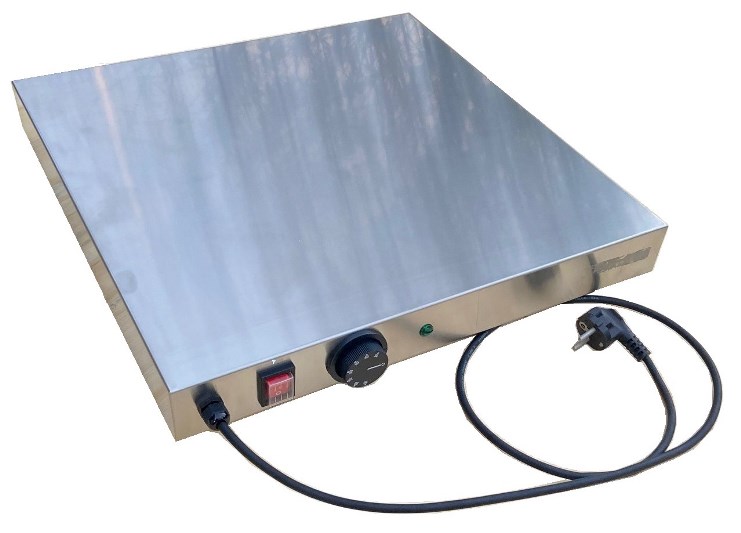

- At the front of the heating table you will find the electrical connection to the mains supply. Always make sure that the socket has an earth connection. The implementation of such a socket can differ per country; some countries use "edge grounding" and some countries use "pin grounding". The supplied cord is suitable for edge grounding (Dutch: "randaarde"). If this plug does not fit into your socket, you must have another plug fitted to the cord by a recognized electrical company..

- The "on-off" switch turns the electrical circuit of the heating plate on and off. When the switch is "off", there can be no voltage on the heating elements. When the switch is "on", a light will illuminate. There is no light in the "off" position.

- The desired temperature can be set between 30°C and 90°C with the thermostat knob. Turning the thermostat knob operates a switch that is connected to a temperature sensor (filled with liquid) mounted on the underside of the stainless steel plate. Precise temperature control is not possible due to the design of the thermostat (liquid thermostat). Electronic thermostats have a much more accurate control range (see heating table VTS). As soon as the hot plate, through cooling, has reached a certain temperature (set with the button), the power is switched on by the thermostat. Subsequently, the full electrical power is used to heat the hot plate to a certain maximum value, which is related to the setting of the thermostat knob. Once that value is reached, the power supply stops and the device cools down again until the power is turned back on. This method creates a "cycling" in the temperature. It is possible that the temperature deviates by as much as 10 to 15 degrees from the set temperature.

- The CE mark is indicated on the type plate, as well as the most important values, such as voltage, current, serial number and type.

- The top plate may be hot. Therefore always be careful. Care should be taken, especially when the lamp of the switch is on. However, if the switch is turned off, the heating table may remain hot for a while. .

- Do not use water or etching acid near this device. Water can cause electrical faults in the appliance..

- No asbestos-containing insulation materials are used in this device.

STANDARDS AND REGULATIONS

The manufacturer of the above equipment hereby declares;

Polymetaal

Postbus 694

2300 AR Leiden

Nederland

, that -these appliances comply with the European Standard IEC 335-1 "Safety of household and similar electrical appliances"

-these devices have been carried out in compliance with the rules arising from the CE standard (Machinery Directives and Magnetic Compatibility Directive)

-these devices bear the CE mark |